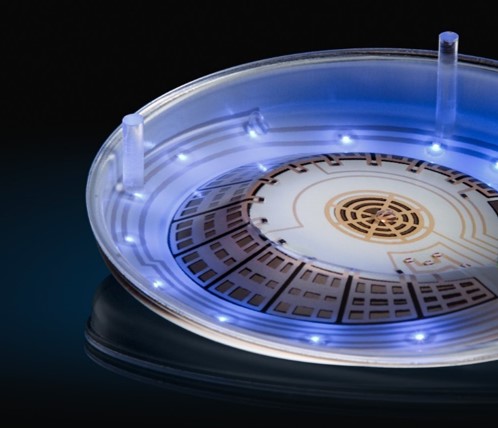

TactoTek is engaged with leading global brands in the development of injection-molded structural electronics solutions for a wide range of markets, including Internet of Things (IoT), automotive, and wearable technology. Whether they include sensors, controls, antennae, circuitry, integrated circuits, or lighting features, TactoTek enables designs that stand out in the marketplace.

Suo-Anttila brings a strong background in the commercialization of new technologies that quickly ramp to large-scale mass production. Past projects include 3D Molded Interconnected Device (MID) technology and printed antennas as well as a wide range of 3D circuit technologies.

According to Suo-Anttila, “TactoTek’s promise of mass producing 3D smart plastic structures is very intriguing. As I learned more about the company and its technology, it became clear that this is a very important solution that can significantly change the market. Moreover, that change comes without requiring massive investments in capital equipment.”

Benefits of TactoTek’s structural electronics solution include design freedom, durability, and space-efficient, lightweight designs—benefits that can be realized using standard injection molding and in-mold labeling equipment.

“Marko has already accelerated TactoTek’s path toward large-scale mass production,” noted Jussi Harvela, CEO of TactoTek. “Whether scaling operations in Finland, or supporting TactoTek-licensed manufacturers in Asia, the Americas, and Europe, he has the ability to move quickly and anticipate the needs of our customers and partners.”

TactoTek prototypes and manufactures products in its Oulu, Finland, factory that include a complete range of production capabilities; mass production can be performed by TactoTek or licensed to TactoTek-certified facilities.